ASAP III: CBRNe Screening for Mail Rooms

The Next Generation in Mail Threat Detection

Is your mail room protected against CBRNe threats? Biowarfare agents, toxic chemicals, and explosives can turn up in the mailrooms of high-value targets such as corporations, banks, and government agencies - harming staff, shutting down businesses, and contaminating buildings for months. In today's world, organizations need protection from such threats.

Research International's ASAP III system for mail rooms is the latest generation of mail room CBRNe protection, offering:

- Significantly reduced cost of consumables

- Reduced testing frequency

- State-of-the-art UV-based biodetection

- Automatic, immediate biocollection when a threat is detected

- Testing for up to eight biothreat agents simultaneously

- Proprietary machine-vision bioidentification technology

- Effective, rapid testing: results in 30 minutes or less

- Minimal work flow disruption

- Control software

- Multiple options for additional testing: Chemical, drugs of abuse, explosives, radiological and nuclear

Reducing the cost of consumables: With ASAP III, biological testing is only required when the built-in bioaerosol detector senses a threat. Instead of testing every batch of mail, testing is reduced to as little as once or twice per month.

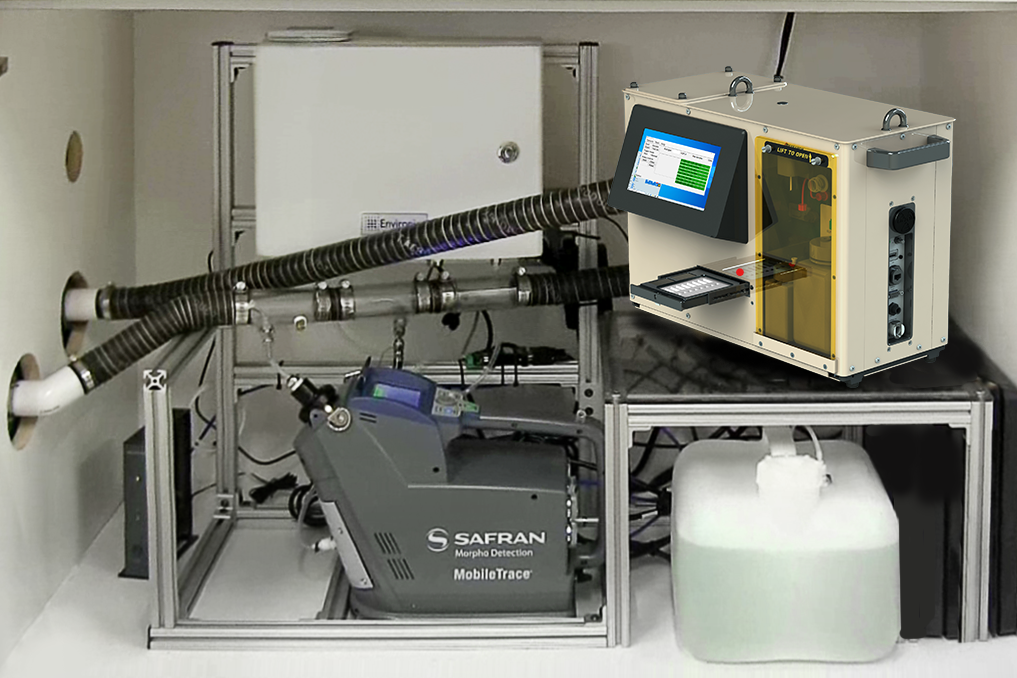

How we do it: The key is Research International's BioHawk® LF integrated biodetector/collector/identifier. This sophisticated instrument combines three Research International proprietary technologies: 1) UV‑based bioaerosol detection capability; 2) automated cyclonic wet sample collection; and 3) machine-vision test reading capability.

Earlier screening systems required biological testing of each batch of mail. With ASAP III, testing only occurs when a biothreat is detected. The BioHawk® LF then automatically tests for up to eight of the most common biothreat agents simultaenously.

Chemical, explosive particle, drugs of abuse, radiation: These optional CRNE components of the system will detect, identify and report in seconds. Expandable default libraries screen for dozens of chemical warfare agents, toxic industrial chemicals, and drugs of abuse. Radiation is detected and reported in less than one second.

Worker safety: The ASAP III system is typically housed in a negative pressure room equipped with a down draft table, custom designed for your requirements. An air sampling module in the system continuously samples air drawn into the downdraft table while mail is being jogged or opened over the table’s perforated top surface, providing appropriate samples to the biological identification components, while ensuring that any potential toxins are immediately drawn away from workers.

Fast, real-time processing: The ASAP III system can process thousands of pieces of mail per hour. Sampling operates continuously until processing of a batch of mail is complete, whether it is a few or several hours.

Low consumables cost: The use consumables in the ASAP III system is minimized by testing only when the biodetector has observed a threat.

Minimal staff training: ASAP III is designed to be operated by general mailroom personnel and is fully automated, requiring little operator assistance.

Control software: Our proprietary ASAP III control software monitors all subsystems and allows the user to adjust parameters as necessary. Easy to install and use.

DOWNLOAD DATA SHEET • REQUEST QUOTE

Subsystem Features

Control SoftwareThe customizable ASAP III system can be configured with any or all of the subsystems shown here. All installed subsystems are integrated and monitored by Research International's proprietary ASAP control software.

|

Biodetector/Collector/Identifier

|

Chemical Detector

|

Radiation Detector

|

Explosives & Drugs of Abuse Detector

|

Typical Applications

- Clean Rooms

- Government or corporate mailrooms

- Critical infrastructure protection

- Food processing

- Homeland security

- Indoor air quality

Resources

- ASAP III System Data Sheet

- ASAP III Photo Gallery

- White Paper: "Bio-Safety in the Mail Room Using the SAMARI Negative Pressure Mail Room and ASAP II Automated Bio-Identification System"

- We offer customized seminars on ASAP III postal processing systems. Download our Postal Seminar Data Sheet, or visit our Postal Processing Seminar page.

- More information on the Biohawk LF automated biodetector/collector/identifier used in the ASAP III system

- More information about negative pressure mail rooms

Specifications

Specifications for ASAP III Threat Identification System

| Parameter | Value |

|---|---|

| Use profile: | Automated, programmed, continuous monitoring and identification of targeted toxins, viruses, bacteria, spores, industrial chemicals, explosives, and nuclear materials. Continuous or batch sample examination supported. |

| Duty cycle: | Continuous. Functional availability > 99.3%. Calculated as total work time the system is functional averaged over a 90 calendar day period. |

| System control: | ASAP III software controls equipment, reports alarms on screen, and communicates results. Large green/amber status light; annunciator optional. |

| Aerosol biodetector : | UV bio-fluorescence detector. Average time-to-alarm is 15-30 secs. Will detect 20 ACPLA bioaerosol levels with 90% or better probability at a background alarm rate of 1 per month. |

| Air sampling rate (collector): | 300 LPM from downdraft table or alternate sources. |

| Air sampling rate (biodetector): | 1.2 liters/min. |

| Sample preparation: | Sample preparation for bioassay is fully automated. |

| Bioassay method (confirmation only): | A bioassay is only required when the bioaerosol detector observes a potential threat, typically about once per month in mail rooms. Testing is done by automatic robotic lateral flow immunoassay for up to 8 biowarfare agents simultaneously. Time to result: 10 - 25 minutes. |

| Toxic industrial chemicals subsystem (optional): | Ion mobility spectrometry or long baseline infrared spectrometry. Gas libraries of 15 to 40 targets, depending on technology used. Analysis time less than 10 seconds. |

| Explosives subsystem (optional): | Ion trap mobility spectrometer; analysis time = 8 seconds. |

| Nuclear materials subsystem: | Area and portal styles available. Typical specifications: 0.05 to 3.0 MeV gamma detection window. Detect 360 kBq of Cs-137 and 6 gm Pu(2); neutron detection optional. |

| Communication: | RS-232 bi-directional serial link is standard. |

| Data storage/ programmability: | Raw/processed data storage. Operating protocols are RS-232 re-programmable. |

| Fluids storage: | 5-day supply of distilled water for aerosol collector. |

| Software interface: | Windows® user interface. |

| Physical size: | Varies. Usually installed as an under-counter system with video monitor on countertop. |

| Temperature range: | Operating: 5°C to 40°C; instrument storage: -29°C to 66°C. |

| Communication: | RS-232 bi-directional serial link is standard. |

| Data storage/ programmability: | Raw/processed data storage. Operating protocols are RS-232 re-programmable. |

| Humidity: | 5% to 95%, non-condensing. |

| Power consumption: | Less than 100 W @ 115 VAC, nominal, excluding X-ray. X-ray system requires 183-253 VAC, 50 Hz. 10 amp max. |

Research International, Inc. reserves the right to change specifications or product source without prior notice. |

|